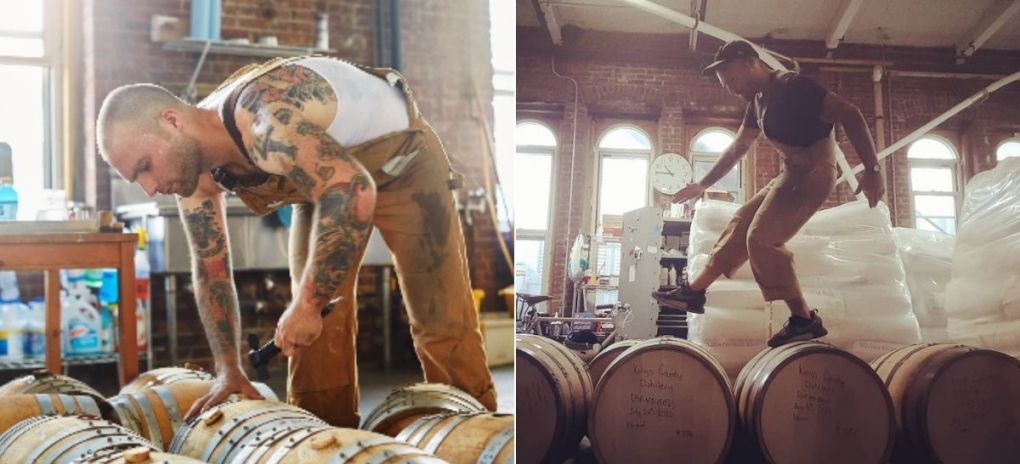

29/01/2022 Head Distiller of Jettywave Distillery, Anthony Marinese shares what it takes to be a Distiller and How the role has transformed over the years.

Bartending for more than ten years, Anthony Marinese started his career in 2012 in San Francisco with a curiosity for alcohol. With a Diploma in Craft Distillation, he further started distilling his own Moonshine which landed him a job at the Kings County Distillery in New York. A few years later, Anthony published his own book “Pop Cocktail - 60 Recipes inspired by Film and Television” and is the Head Distiller at Jettywave Distillery, a craft distillery in Half Moon Bay, California which he has built with his own expertise. He also provides consultation and shares his expertise with distillers to open new distilleries.

What has your distilling career been like? Tell us a little about your background.

Well, in 2012 I was a Cocktail Bartender in San Francisco and started to become very curious about how alcohol was made. This curiosity turned into an obsession, and I bought a small Portuguese still, and every book I could find on the topic. I started making some really awful moonshine but kept learning and reading. One day I found The Kings County Distillery Guide to Urban Moonshining. There were a few passages in this book that changed some key things in my process. I began making some really delicious moonshine and selling it to the local motorcycle clubs, hippies, and various other subculture types. It became really popular. In 2014 I moved to New York City, and my first stop was Kings County Distillery. I took the tour and totally geeked out. After the tour, I introduced myself to the owner, Colin, who had co-written the book that had helped me so much. I gave him a jar of my moonshine as a thank you for writing his book, and he tried it and liked it. He gave me a job at the bottling line, then in barrel storage. Meanwhile, I was coming in on my own time learning from another distiller there named Matthew "Snake".

One day Snake quit, and Colin called me and offered me a full-time position as a distiller. After a couple of years of distilling in Brooklyn, I moved to Chile and opened Destileria Husares. In 2018, the social and political climate in Chile became very tumultuous, and my wife and I decided to move to New York, and I distilled again at Kings County until 2021. I have since moved to Half Moon Bay, Ca, and I have built and opened Jettywave Distillery. The distillery I opened in Chile is still operating, and I often work as a Consultant and Distilling instructor for newly opening distilleries.

How do you think the Spirits industry has evolved?

I feel that the spirits consumer has changed, and people working in the spirits industry, in general, are finding really clever ways of keeping up. The average customer seems more well-informed, and willing to try new things. A period of no going out and no bars made people rethink their home bar situation. A variety of bottles and ingredients at home makes quarantine more palatable I feel. I feel that there is, now more than ever, demand for options. People seem to be into variety and less into loyalty to one brand. I feel that this is sort of facilitating more of a comradery than competition between new small brands. Being able to ship alcohol from the distillery to the customer directly has also been huge.

Tell us a little about your day-to-day role.

I get in at 8 AM and start my mash water heating. I then pump a fermented and ready mash from a fermenter, into my strip still, and then I fire it up. While my mash water is heating, I get all of my grains ground up, and my non-malted grains mixed into the heated mash water. I then fill my spirit still with the previous day’s low wines and feints and fire it up as well. By this time, my mash has boiled, and I turn it off and let it spin and sit at its temperature for an hour. This is when I clean everything that I just messed up moving mash and grains around.

When I finish this, my spirit still has begun to produce, and so I give it my attention until I've gotten into my Hearts section of my spirit run. I then lower the temperature on my mash, add my malted grains, and let that sit an hour, spinning around. I then have time to take inventory, make orders, read and write emails, and tend to other daily logistical tasks of a person managing a production floor. During all this time, the strip still is running smoothly and does not require attention.

After an hour, I begin to cool my mash, all this while keeping my spirit running in mind. After the Hearts portion of my spirit run has finished, and I am now collecting the tails, I pump my cooled mash into the same fermenter that I emptied earlier into the strip still, and pitch some yeast on top. After that, I clean everything and refill my mash cooker with water to be preheated for the next day. I will then proof down and barrel the spirit produced that day and put the barrel away in our bonded barrel aging room. When my strip still has finished and my tails have run out, I will let the stills cool and then clean them out. I then register in a computer everything that happened in the day, clean the floor, feed the cat, lock up, and leave around 5 or 6 pm.

What's unique about your Distillery that you like?

The distillery I work in now is indeed a unique place. We have literally built most of it ourselves, but one of my favorite parts about it is how we ferment our mash. We open ferment, on the grain, in big tubs made from old-growth, ancient California coastal redwood. I know what you're thinking, and no, it wasn't newly harvested wood. Those remaining old-growth redwood trees are endangered, and protected, as they should be.

A big reason that they are endangered is that in the 1910s and '20s most of these ancient trees were cut down, and a lot of them were made into water tanks. Fast forward to the 1980s, and most of these water tanks have been replaced by plastic, and the wood disassembled and tossed aside to rot. I went around the coast here, hunting down boards of this old "garbage" wood and I shaved all the boards down until I found this beautiful old-growth redwood underneath. I then made all of this wood into 3 fermenters and didn't use any glue or a single nail. At Jettywave distillery, every product we make starts out fermented in one of these 3 tubs, spending 4 days with this ancient sacred wood, before it is pot distilled in really small batches.

What were some of the challenges you faced when you distilled your first spirit?

My biggest challenge when doing my first distillation is a hard one to nail down. There was a lot. Making the cuts was super confusing, getting the right flow rate was challenging, managing the water to cool my condenser was a huge pain, and being patient was a huge issue. One thing no one tells you is that your Hearts portion is going to end up being only about 8-10% of the volume of the fermented mash you started with. That and how much time it takes to just wait and watch for drops to start falling.

One huge issue was the legality of it. Home distilling being illegal makes it really difficult to learn how to do it. That's one big difference between brewing and distilling, it's totally legal to learn brewing on your own at home. Because of this, at that time, there wasn't really a lot of information written for people wanting to learn distilling on their own with the most basic equipment. That made it really intimidating to get started. I read every book I could find on the topic, but most were written for big distilling projects, or people looking to open a big operation. That isn't the story so much anymore.

How do you think a distiller can help in driving marketing and sales personally?

With the current scenario of better-informed customers, comes more curious customers as well. I think that part of a head distiller's position should be marketing. It should include representing the brand at events and competitions, or online through social media, or events online. A head distiller should lead VIP tours, and tastings as well. Distillers should make themselves known around their locality, and at least introduce themselves to the people selling their products. From my experience, people really love and appreciate your alcohol in a new way when they hear about what they are drinking from the person who made it.

What are some of the essential skills required to distill?

Care, patience and attention to detail.

Also some kind of mechanical ability. Every day something will go wrong. It really helps to be able to think on your feet and figure out how to solve problems as they come up. Also, being humble, and realizing that all distillers start somewhere, and no distiller knows everything, is crucial for mental and emotional health.

Define a Good Distiller.

A good distiller is patient, meticulous, tidy, friendly to guests, and respectful to coworkers. A good distiller strictly follows protocols both in the process itself, and to do with safety. A good distiller pays attention, comes to work on time, and leaves with everything in order and ready for the next shift. A good distiller loves to distill and doesn't mind getting dirty.

What advice would you give to future distillers?

1. "Asking another distiller for help with an easy "dumb" question will make you feel stupid once, not asking will make you feel stupid forever." I'm sure something like that quote came from somewhere else. I can't remember where, but it's very applicable to distilling.

2. Take good notes, wear comfortable work boots and keep your tools and equipment clean.

3. There are a million ways to distill, and a million opinions on the "correct" way to do it. The truth is, there are many many correct ways to distill. The thing is, every different method will get different end results. The real trick is to know what things you are trying to accomplish and figure out along the way the most efficient way to do them. Your methods and techniques will continually evolve as you keep finding ways to make your own life easier.

Which is your go-to drink and what is the perfect setting you enjoy it in?

That's a loaded question haha. The answer to that changes often. Currently, I live in a place that is seemingly in a state of perpetual autumn. My go-to (when I'm not drinking Bourbon or Rye neat) is a Hot Toddy. I love it outside, and at a bar-b-que or other outside home-based gathering, when it gets dark, the temperature is dropping, people are getting cold. It's so nice to have a warm mug in hand, and Hot Toddy in the belly especially after everyone has eaten. Hot Toddies are great at the end of the party, right before sleeping too.

What do you do when you are not distilling?

I have been doing more consulting lately. I really love helping people find their equipment, and train and teach their employees. I also really like to hang out with my wife, and we do a fair bit of traveling. A lot of my spare time is also used to make oil paintings, go sailing. I run a lot and read fewer books than I'd like to. I'm also a big fan of a midday nap when I can squeeze it in.

What is your idea of a good life?

To me, a good life is to love and be loved. It is to find success professionally in something you love to do. It is working hard, and having that work be recognized, appreciated, and fairly compensated for. It is also being able to use your skills and talents to contribute to the betterment of your community. It is having a good balance between work life, and personal life where both sides get the attention they deserve.

International and domestic spirits brands are invited to register, to take advantage of the early bird pricing that is on right now. Here is how to enter.